Professional equipment manufacturer specializing in the development of Tube filler and sealer machines !

- Home

- Product

- Filling packing line

- ZHCJ-1926W Weight Filling Machine

Products Category

- Tube Filler & Sealer Machine

- Vial Filling And Capping Machine

- Chemical & Cosmetology Machine

- Bag Packaging Machine

- Feeding Machine

- Liquid Filling Machine

- Capping Machine

- Labeling Machine

- Filling Packaging Line

- Cartoning Machine

- Automatic Case Packer

- Cream Vacuum Emulsification Blender

- Automatic Aerosol Filler

Products Details

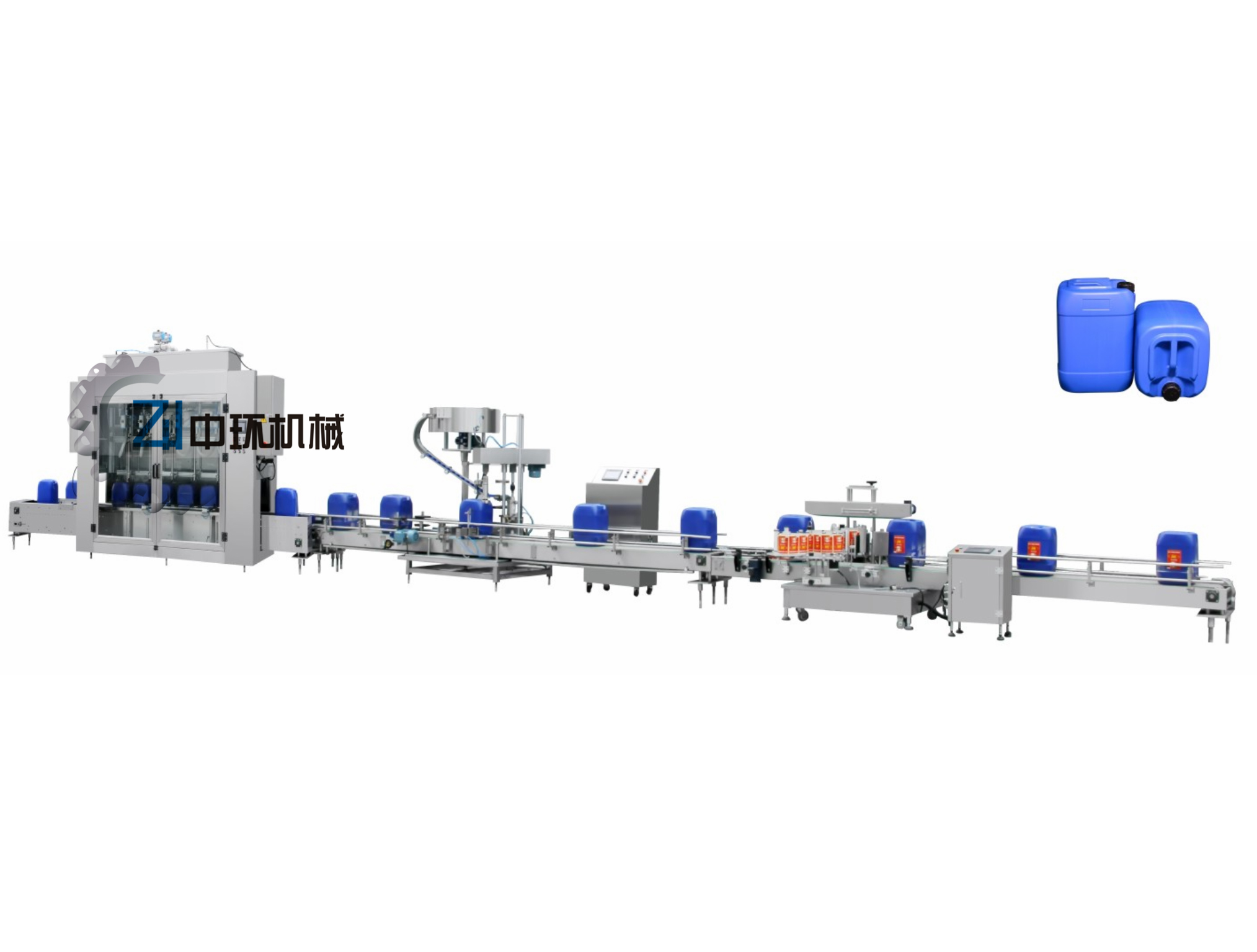

ZHCJ-1926W Weight Filling Machine

- Category Name: Filling packing line

- Category Name: ceo@zhpackaging.com

Major Characteristics:

◆This weighing filling machine is for filling

◆ Each filling head has the weigh and feedback system,

each filling head can be regulated

◆This type filler adopts PLC to control, touch screen

control panel

◆ It applies dive method to fill and it reduces foam.

◆ This

machine adopts PLC and touch screen control panel, so it is convenient to set.

◆ Each filling head has the weigh and feedback system,

each filling head can be regulated.

◆ Photoelectric sensor, approximate switch and other

electric elements are of the international famous brands. It ensures no

container miss filling. The host machine will alarm if there is any container

blocked.

◆It applies dive method to fill and it reduces foam; it is

suitable for various kinds of filling products.

◆ The whole machine meets GMP standard, it is easy to

clean and maintain, and the parts which contact with the filling material are

made of high quality stainless steel. The whole machine is safe, eco-friendly

and sanitary. It adapts to various kinds of working places.

Main Performance parameter:

Outline Dimension (L×W×H):

Number of filling Head:4

Suitable bottle:Length:

Width:

Height:

Diameter of bottle mouth:≥Φ

Suitabe range:

Production capacity:≤480bottles/hour(tested by water)

Filling Error:±15ml

Voltage:220V;50Hz

Power of host machine:3kw

Pneumatic (air-operated) source:0.5Mpa~0.65Mpa clean and Stably compressed air

Welcome to our website. If you have any requests or suggestions,please feel free to email us at ceo@zhpackaging.com or use the following enquiry form. Please allow us to provide you with the best service.