Professional equipment manufacturer specializing in the development of Tube filler and sealer machines !

- Home

- Product

- Labeling machine

- ZHSP-100Y Sleeve Inserting Machine

Products Category

- Tube Filler & Sealer Machine

- Vial Filling And Capping Machine

- Chemical & Cosmetology Machine

- Bag Packaging Machine

- Feeding Machine

- Liquid Filling Machine

- Capping Machine

- Labeling Machine

- Filling Packaging Line

- Cartoning Machine

- Automatic Case Packer

- Cream Vacuum Emulsification Blender

- Automatic Aerosol Filler

Products Details

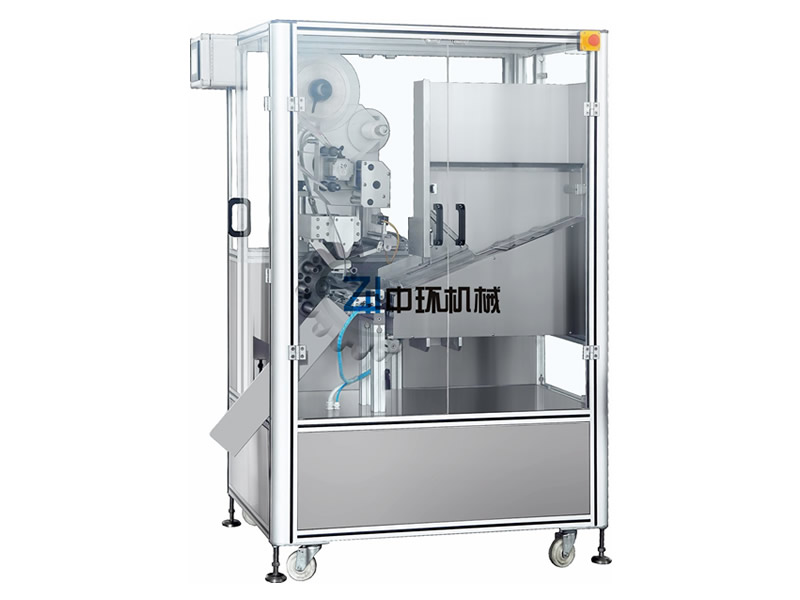

ZHSP-100Y Sleeve Inserting Machine

- Category Name: Labeling machine

- Category Name: ceo@zhpackaging.com

Synchronous transmission system with a strap, changing any strap can finish in 3 min. it maintains more easily and simply, and it does not affect to manufacture.

It is suitable for the containers of φ30-120mm. The cutting seat need not change and debug, and has priority over congeneric productions. The new reamer cuts smoothly and constringency more beautiful.

Steam shrinkage furnace,safe,easy,efficient!high energy sources efficient:it can finish shrinkage perfectly with lowest energy sources.

Safety design:special Thermal insulation layer design,furnace outside keeps normal temperature,doesn’t hurt operator at all.special door clamp design,keep energy sources inside and airproof.

Originate automatic mechanism of incepting label (option) reduces labor intensity consumedly.

With particular design of transmission mechanism, cutting seat and reamer, it shows disdain for the same trade.

With servomotor, high speed, excellent stability.

With high-tech microcomputer controlling, the rate of trouble is low, and servicing is speedy.

Techno-parameter:

Main machine:

Speed:100bpm

Power supply:φ AC220V 50/60hz

Power consumption: 3KW

Outside size:2400(L)*9500(W)*2500(H)

Quantity of air consumed:50kg/hr

ContainerRange: 30—85mm (Dia.)

LabelRange:40—240mm (L)

0.035—0.082mm (Thickness)

Steam shrinkage furnace:

Power supply:φ AC220V 50/60hz

Power consumption: 0.75KW

Outside size:2000(L)*400(W)*2100(H)

Quantity of air consumed:35kg/hr

Pressure of steam:5kg

It is suitable for the containers of φ30-120mm. The cutting seat need not change and debug, and has priority over congeneric productions. The new reamer cuts smoothly and constringency more beautiful.

Steam shrinkage furnace,safe,easy,efficient!high energy sources efficient:it can finish shrinkage perfectly with lowest energy sources.

Safety design:special Thermal insulation layer design,furnace outside keeps normal temperature,doesn’t hurt operator at all.special door clamp design,keep energy sources inside and airproof.

Originate automatic mechanism of incepting label (option) reduces labor intensity consumedly.

With particular design of transmission mechanism, cutting seat and reamer, it shows disdain for the same trade.

With servomotor, high speed, excellent stability.

With high-tech microcomputer controlling, the rate of trouble is low, and servicing is speedy.

Techno-parameter:

Main machine:

Speed:100bpm

Power supply:φ AC220V 50/60hz

Power consumption: 3KW

Outside size:2400(L)*9500(W)*2500(H)

Quantity of air consumed:50kg/hr

ContainerRange: 30—85mm (Dia.)

LabelRange:40—240mm (L)

0.035—0.082mm (Thickness)

Steam shrinkage furnace:

Power supply:φ AC220V 50/60hz

Power consumption: 0.75KW

Outside size:2000(L)*400(W)*2100(H)

Quantity of air consumed:35kg/hr

Pressure of steam:5kg

Welcome to our website. If you have any requests or suggestions,please feel free to email us at ceo@zhpackaging.com or use the following enquiry form. Please allow us to provide you with the best service.